I’ve been an engineer and manager for more than 35 years. When I talk to my friends and family about my job, I find that most of them don’t understand how the oil and natural gas extraction process works. Everyone talks about fracking, but that’s only one step of a larger process.

Check out the seven steps of oil and natural gas extraction below:

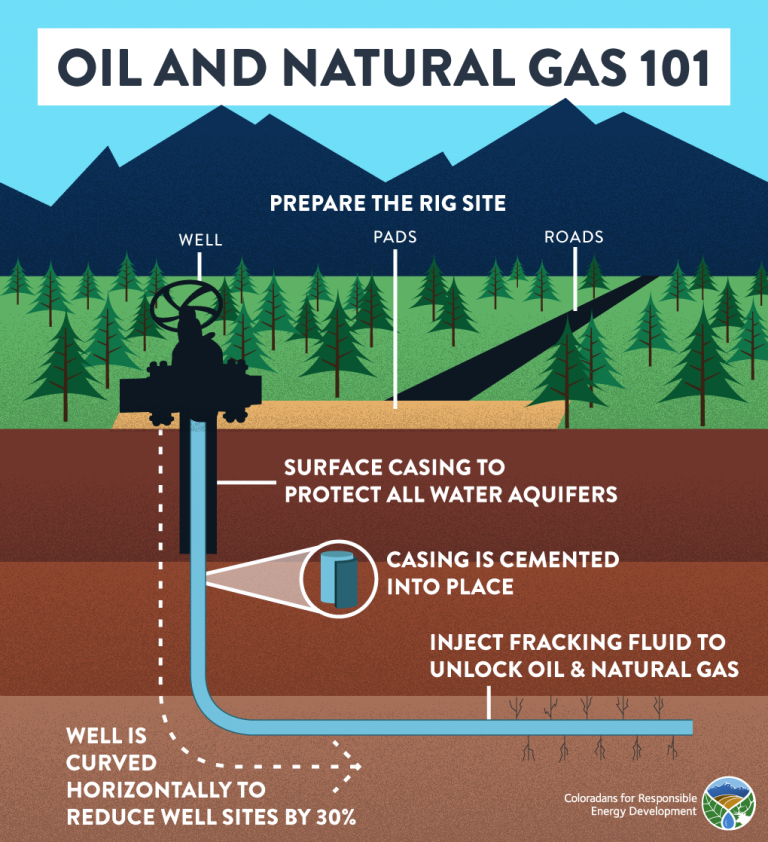

STEP 1: Preparing the Rig Site

The aboveground infrastructure—pads and access roads—are built, setting up the land for the next step: drilling. From start to finish, everything from traffic plans and designated access roads to noise barriers and safety procedures is carefully planned and monitored according to state and local laws.

STEP 2: Drilling

First the drill rig is brought to the location—maybe 20 or 30 truck loads—and put together. Now It’s time to build the infrastructure necessary to unlock the oil and natural gas trapped more than a mile below the ground. A well is drilled straight down into the ground beneath the pad. The first stage is to drill what is called the surface hole down to a depth of 100 feet below the deepest known aquifer. A steel casing is then cemented in place so there is no risk of polluting precious water aquifers.

After this the “long hole” is drilled and after reaching a depth about 1000 feet above the underground area where oil and natural gas is trapped, the hole is directionally steered to turn it horizontal and out—maybe another mile or two in distance—following the same rock bed. There’s a phenomenal amount of technology required to keep the hole drilling in the same 10-foot-interval for two miles, but this process allows the well to access oil and natural gas across a longer distance rather than just the energy directly beneath the well pad.

Unlike vertical drilling, horizontal drilling minimizes the impact and scale of aboveground land disturbance by allowing drillers to use only one drill pad for multiple wells instead of multiple pads having a single well each. These technological advancements mean today’s well sites are far fewer in number and also smaller than they used to be just 10 or 20 years ago.

STEP 3: Cementing and Testing

Once the target distance is reached, the drill pipe is removed and steel pipe is pushed to the bottom. This “well casing” is cemented in place. Rigorous tests are performed to ensure the pipe is impermeable before any production of natural gas or oil can occur.

STEP 4: Well Completion

Before drillers can tap the oil and natural gas, a perforating gun is typically lowered into the ground and fired into the rock layer in the deepest part of the well, creating holes that connect the rock holding the oil and natural gas and the wellhead.

STEP 5: Fracking

Now that the first stage of the well is open, it’s time to unlock the oil and natural gas that has been trapped in the rock. Using specialized instruments to monitor pressure and data from the well in real time, fracking fluid, which is 99.5% water and sand and 0.5% chemicals, many of which are found in everyday household products, is pumped at high pressure through the perforating holes to create paper-thin cracks in the shale rock, freeing the oil and natural gas trapped inside.

The cycles of steps 4 and 5 are repeated, gradually working up the hole until all the lateral length of the wellbore has been fracked. This might be 20 or 30 times—but a process that typically takes only a few days to finish.

STEP 6: Production and Fracking Fluid Recycling

Once fracking is completed, production begins. Oil and natural gas flows up from the well bore and fracturing fluid is then recovered and recycled and used in other fracking operations.

Once fracking is complete, the production site shrinks to the size of about a two-car garage.

STEP 7: Well Abandonment and Land Restoration

When all of the recovered oil and natural gas has been produced, Colorado law requires that the well is permanently plugged and the land is returned to the way it was before the drilling operations started. The land can then be used for other activities and there is no sign that a well was once there.

Producing Colorado’s oil and natural gas energy is something that can be done safely while contributing hundreds of millions of dollars to the state’s tax base.

Dr. C. Mark Pearson studied mining engineering at the Camborne School of Mines (UK) where he received his BS degree, and later a PhD for his studies on the application of fracking to geothermal energy extraction. He has since worked in the oil and natural gas industry for over 35 years working projects all around the world. From 1995-1997, he was a professor in the Petroleum Engineering Department at the Colorado School of Mines.

Learn More!

Want to learn more about fracking? What is in fracking fluid? How much water does fracking use? Click here to get the facts on fracking in Colorado – from our state’s stringent regulations to how it powers our economy and supports our communities.